Rotary Atomizer Systems

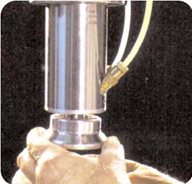

Rotary Atomisers have been used for many years in industrial applications. In electrostatics, the coating fluid is applied to a rotating bowl, then spun out to the bowl's edge where it is subjected to an intense electrostatic energy field. The cup-shaped atomiser is rotated at high speeds (up to 40,000 rpm) using a friction-free air turbine. A combination of centrifugal and electrostatic energy is used to atomise and uniformly distribute coating fluids over the target surface. The resultant dense, uniformly distributed pattern of charged fluid particles is strongly attracted to the grounded target, providing almost 100% transfer efficiency.

The main advantage of the rotary atomiser is its ability to maintain uniform distribution down to extremely low coating weights: as low as 3 mg/m2 and generally up to 200 mg/m2, with excellent control characteristics. In addition, many types of coatings can be used, including waxes and water-based fluids. Another advantage is that the rotary atomiser has excellent response time to maintain coating weight where fast strip accelerations / decelerations are required.